Tom Wolf, Agrimetrix Research & Training, Saskatoon and Jason Deveau, Ontario Ministry of Agriculture, Simcoe

By now you may have heard cautionary statements about the use of dicamba on Xtend soybeans. There appears to be a lot of concern about spray drift. What is this all about?

The herbicide dicamba has been a part of Canadian agriculture for two generations. First discovered in 1958 and introduced into the U.S. in 1967, dicamba has been known as Banvel and Banvel II in Canada (Banvel and Clarity in U.S.), and is a common ingredient in both agricultural and lawn weed control products. The original forms of dicamba, the dimethylamine (DMA, Banvel) and diglycolamine (DGA, Banvel II) salts are known to be volatile, with the DGA salt a three-fold improvement on the DMA salt.

Dicamba has now been reintroduced as two new formulations with the advent dicamba-tolerant Roundup Ready 2 Xtend soybeans. XtendiMax with VaporGrip by Monsanto is the DGA salt with a vapour-reducing adjuvant. It has been tested by Monsanto and their data show it has significantly less vapour losses than the original DGA formulation. The product is licensed to DuPont under the name FeXapan herbicide plus VaporGrip Technology, but its availability is unknown at this time.

BASF’s new low-volatile formulation of dicamba is Engenia. It’s a new low-volatile salt; bisaminopropyl methylamine, BAPMA for short. It has significantly less vapour losses than the DGA salt, about a three-fold improvement according to Dr. Kevin Bradley, University of Missouri.

The underlying problem with the use of dicamba is the high sensitivity of conventional soybeans to the product.

Work by Dr. Bradley in Missouri and others has shown that soybeans can show visual damage symptoms at 1/20,000 of the field rate, and yield losses from vapour and particle drift at 1/1000 and 1/100 of the label rate, depending on the soybean growth stage. The vapour aspect is being managed by these new dicamba formulations, and it will be illegal to apply the older products (Banvel, Banvel II) to the new cultivars.

Despite the new dicamba formulations, spray drift will remain an issue. While these formulations reduce vapour drift, they do not change particle drift. Let’s review the four ways that non-dicamba tolerant soybeans can experience dicamba damage.

1. PHYSICAL OR PARTICLE DRIFT

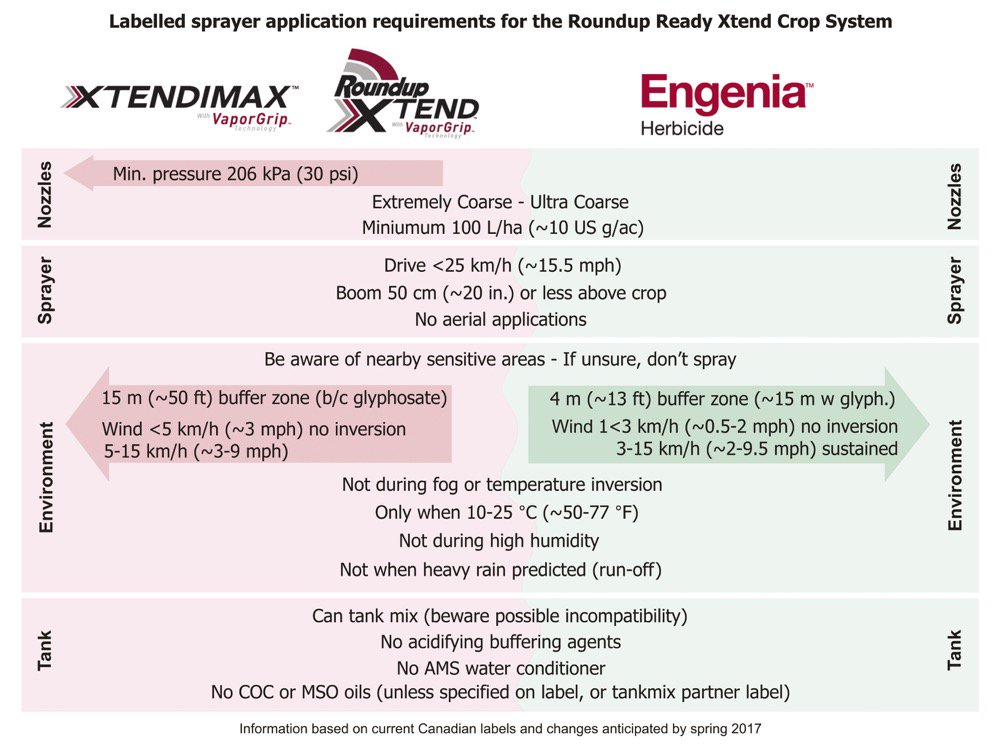

All spray nozzles produce some driftable fine droplets. Low-drift nozzles produce fewer fines, and in Canada, the spray quality recommended for dicamba on Xtend beans is Extremely Coarse (XC) and Ultra Coarse (UC).

Nozzle manufacturers publish their products’ spray qualities, and a good selection of nozzles from all major manufacturers are available. These and other limitations can be reviewed in the label information above.

Note that the U.S. labels are different. Those currently only allow the TeeJet TTI 11004 nozzle at 60 psi or lower to be used.

2. TEMPERATURE INVERSIONS

These atmospheric conditions appear on most summer nights. They begin at dusk, persist and grow overnight, and begin to dissipate after sunrise, and are popular with some applicators because of the associated calm conditions.

The main issue with inversions is that they allow the long-distance movement of a drift cloud without reducing its potency. The resulting damage, which can be the result of particle or vapour drift, has no apparent pattern, having the same severity throughout an affected field.

Under turbulent conditions, normally when it’s sunny or a bit breezy, the spray drift cloud dissipates quickly with distance and damage is limited.

3. VOLATILITY

Volatile products can evaporate, even from dry deposits, for several days after application. The vapour loss depends on temperature, and may be exacerbated by moisture for some products.

We’re hopeful that the vapour aspect of dicamba damage can be managed with the new formulations. But their performance can be undone with some additives. The new labels prohibit the use of acidifying buffering agents or AMS water conditioner, for example, as these have been shown to increase volatility.

Remember that the use of the older, more volatile formulations of dicamba is illegal on the dicamba tolerant soybean cultivars.

4. SPRAYER CONTAMINATION

With even a tiny amount of dicamba capable of causing significant soybean damage, it will be important to thoroughly clean a sprayer after dicamba use and before entering non dicamba tolerant soybeans.

Experiences in Missouri showed that just 250 mL of tank mix left in a tank, presumably diluted in 800 to 1200 gallons (a 12,000 to 18,000 fold dilution), was enough to cause significant soybean yield loss.

Minimizing the remainder volume, then triple or quadruple rinsing with detergent, and also checking screens and flushing boom ends, will be necessary. Check Sprayers101.com for a handy dilution calculator that shows how effective your rinse is.

The stakes are high. Let’s be careful out there. And remember to check Sprayers101.com for any information relating to spray drift, inversions and tank cleanout.